How to Repair Pcb Traces and Make Them Solderable Again?

Printed circuit boards are easily damaged. All it takes to crack a trace is a little rough handling during installation or removal. It doesn't even accept to be deliberate roughness, some of the plug-in boards simply don't want to enter or exit their sockets without the use of a piddling strength. Apply a petty fleck too much estrus for a piffling too long during the installing or removal of components and the copper trace will lift complimentary of the board'southward substrate. Finding a microscopic fissure in the trace is the about office of making the repair.

In this passage, we will talk about the methods of how to repair the cleaved PCB traces and if you are curious about it, delight check the content we provide below.

If yous want to club PCB product, please check and custom your order online.

Why we accept to repair PCB?

Why bother at all with learning component-level board repairs for PCBs? Don't we live in a throwaway civilisation in which information technology's OK to toss electronics in the landfill at the first sign of trouble?

This is the starting time reason why information technology makes so much sense to acquire everything that you tin about repairing PCBs. People who have a passion for electronics, and for upcycling or getting the maximum lifespan out of something, can find a lot of satisfaction in the procedure of locating damaged tracks or identifying failed board components, replacing them, and restoring a PCB.

On the hobbyist as well every bit the professional side of things, an understanding of how PCBs function and how to restore them is essential if you lot want to learn how to build and maintain your own projects and systems, such as the following:

Garage door openers

Abode theater systems

Speed controllers for powered tools

Televisions

Computers

Electrical engineers have even more than motivation for pursuing a masterful knowledge of this key skill. Both the consumer and commercial mural rely on ever more sophisticated electronic devices, near of which require PCBs. Knowing how to diagnose bug with these boards and repair or replace failed components means that a technician can perform troubleshooting on a broad range of computerized assets and internet of things (IoT) devices.

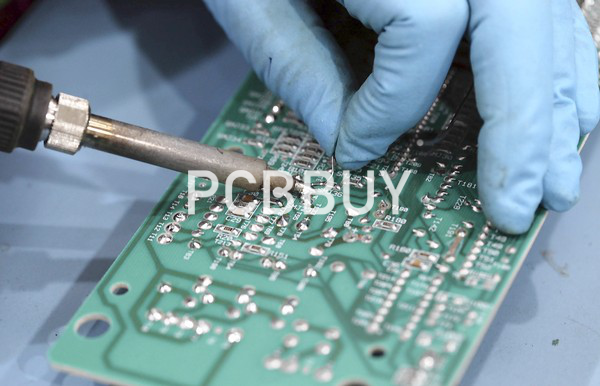

How to repair PCB step by step?

Step 1: Remove the damaged pad or component. First, secure the PCB to your work surface so that it doesn't move effectually while you lot're working on information technology. It'south all-time to utilise tape.

Sometimes, diagnosing a damaged and inoperable PCB requires the application of an oscilloscope to probe the indicate strengths and waveforms at various points to exam for continuity of the circuit across the board. Other times, it's just a matter of looking for a burned surface area that indicates that a failed component or a pad or trace needs to be replaced and rejoined to the existing track on the PCB.

If you detect that one of the components on your PCB isn't performance the way that it should, there's a unproblematic process for removing and replacing it:

Catch the hot air gun and turn it on. Hold it no fewer than 6 inches from the failed component.

After a few seconds, take a pair of tweezers and attempt to lift the component away. If it doesn't come, continue to employ estrus for a few more than seconds and then try over again.

If a PCB pad has been damaged past heat, it's all-time to employ a precipitous knife to carefully remove it. Your priority is to limit the amount of damage that you do to the rail and the other nearby features while still freeing the board from any residual.

Step 2: Make clean the track and remove solder. Once you've removed the damaged pad, keep using your abrupt knife to remove the existing solder. If you lot're not comfortable using a pocketknife for this relatively delicate function of the operation, a sharp-pointed screwdriver or sandpaper with a very fine dust will work, too.

No matter which tool you lot prefer, the result should be a fully exposed rails, free of existing solder, which looks shiny and clean.

Pace 3: Place your copper tape over the rails. After you've removed the damaged track and cleaned off the expanse, it'southward time to place your adhesive copper tape over the elevation of the area that you lot're working with.

Your tape should overlap with the existing track and cover the existing through-hole and a portion of the area surrounding information technology.

Step iv: Solder the joints. From hither, it'south a matter of advisedly soldering the joints where the new copper record joins with the existing track on your restored PCB. Here are a few tips and warnings about this office of the process:

Copper tape melts apace at soldering temperatures, so don't begin until you're sure that you tin can finish this role of the procedure in one get.

Utilize as little heat as possible and work deliberately, but quickly, to reduce the amount of estrus practical.

Step 5: Restore the PCB through-hole. Find a hard implement with a rounded-off end, like a pen or another simple tool. Press down on the area that you've only soldered and rub firmly to ensure that the copper tape is securely affixed to the unabridged pad area. The adhesive should yet be tacky later on y'all've applied oestrus to the area.

With this technique, you'll be able to place where the through-hole is, which you can then pierce with a paper clip or another similar implement.

Step 6: Place and solder your component. If you've followed these steps so far, yous should have a PCB that's been restored to functionality and is gear up to receive your component of choice.

From here, soldering the components should be a familiar process. Nevertheless, y'all'll want to continue your awarding of oestrus equally brief as possible. The new joint that you lot've formed between the freshly affixed copper record/pad and the runway may be somewhat fragile.

Pace 7: Trim excess tape from the repaired expanse. Using your scissors or arts and crafts knife, advisedly cut the agglutinative copper tape down to size to finish the repair. It'southward important to annotation that the joint that you've merely repaired may restore your PCB to functionality, but the pad, track, and joint will never be as structurally sound equally the original board. Nevertheless, you've taken something that many others would discard as junk and given information technology a new lease on life.

Wanna know PCB knowledge? Check and read for more.

Source: https://www.pcbbuy.com/news/How-to-repair-broken-PCB-traces.html

0 Response to "How to Repair Pcb Traces and Make Them Solderable Again?"

Post a Comment